Builder Retaining Wall: Top 7 Proven Solutions for 2025 Success

Why Your Property Needs a Professional Builder Retaining Wall

Finding the right builder retaining wall contractor can make the difference between a structure that lasts decades and one that fails within years. Here’s what you need to know:

Key Factors When Hiring a Retaining Wall Builder:

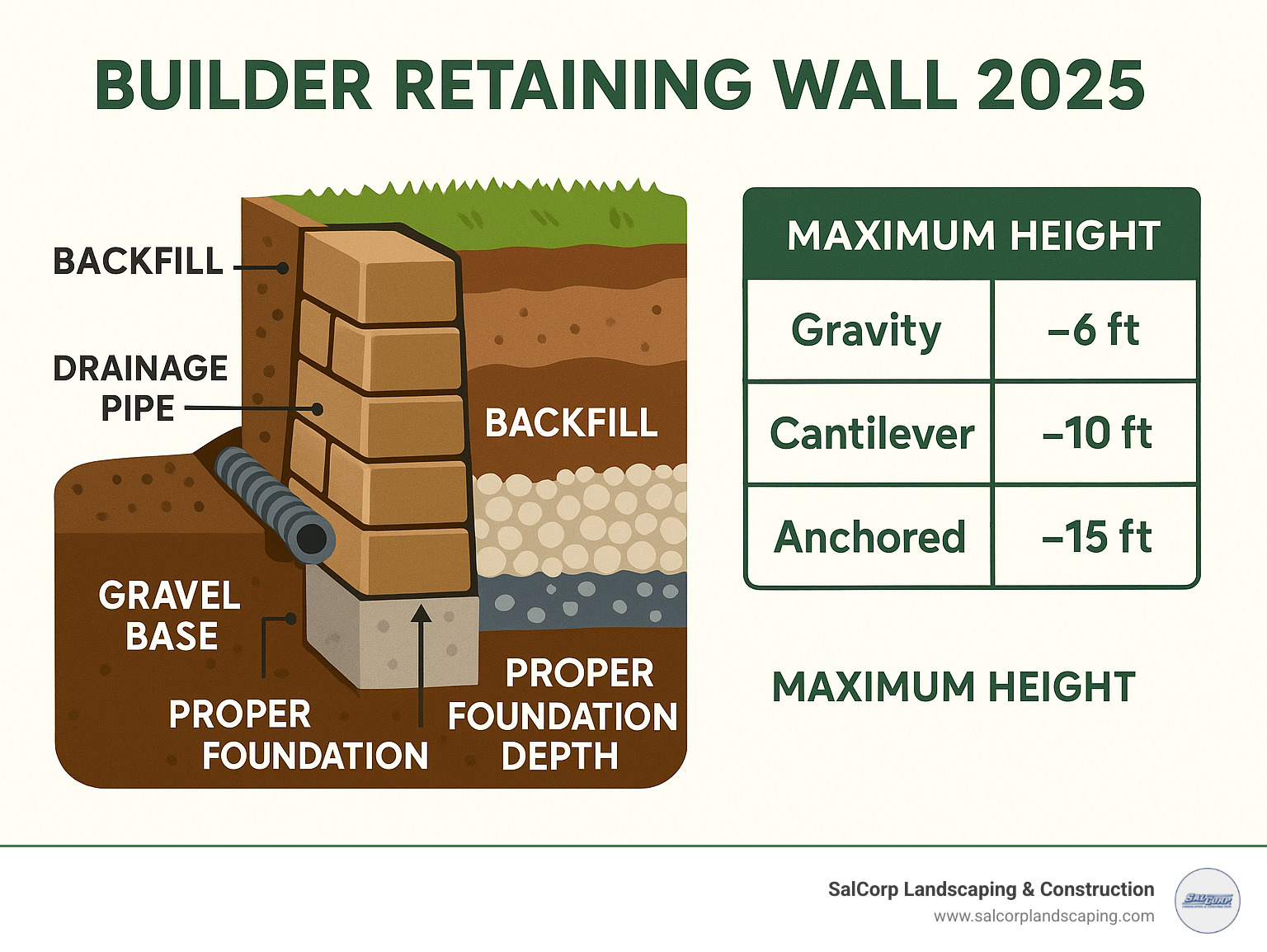

– Experience with your wall type – gravity, cantilever, or anchored systems

– Proper licensing and insurance – especially for walls over 4 feet

– Drainage expertise – the #1 cause of retaining wall failure

– Local permit knowledge – Massachusetts requirements vary by height

– Equipment and materials – plate compactors, geogrid, proper backfill

Whether you’re dealing with a sloping driveway, creating terraced garden beds, or preventing soil erosion, retaining walls serve as critical infrastructure for your property. Retaining walls can increase usable yard space by up to 50% on sloped properties while preventing costly erosion damage and adding significant curb appeal.

The key is understanding that retaining walls are engineered structures fighting constant pressure from soil, water, and gravity. A poorly built wall doesn’t just look bad – it can fail catastrophically, potentially damaging your property or creating safety hazards.

As Sal Musto, owner of SalCorp Landscaping & Construction, I’ve spent over two decades helping Massachusetts property owners solve challenging slope and drainage issues with builder retaining wall solutions.

Common builder retaining wall vocab:

– retaining wall landscaping

– retaining wall design

– what is a retaining wall

Why a Retaining Wall Is More Than a Pretty Face

Most folks see a retaining wall and think “wow, that looks nice” or “great way to make that slope usable.” But here’s what’s really happening: your builder retaining wall is locked in an epic battle against Mother Nature, 24/7.

Soil pressure is the silent heavyweight champion in this fight. Every cubic foot of soil weighs over 100 pounds. Imagine thousands of cubic feet pressing against your wall, especially after a Massachusetts rainstorm when that soil gets waterlogged. The pressure can literally double overnight.

Hydrostatic pressure becomes the real troublemaker. Water doesn’t compress – it just keeps pushing. When water builds up behind a wall without proper drainage, it’s like having a liquid battering ram working around the clock. I’ve seen perfectly good walls that lasted 20+ years suddenly fail because a drainage pipe got clogged.

Here’s the physics lesson: retaining walls work like giant levers. The taller your wall, the easier it becomes to tip over from pressure at the top. This is exactly why gravity wall basics matter so much – these walls rely on their own weight to stay put, fighting physics with pure mass.

Drainage must-haves aren’t optional extras – they’re the difference between a wall that lasts decades and one that becomes an expensive pile of rubble. Every professional builder retaining wall project starts with a drainage plan, not a pretty design.

Properly built retaining walls boost property value significantly while creating usable yard space that didn’t exist before. We’ve helped homeowners transform steep, unusable slopes into gorgeous outdoor living areas.

Want to dive deeper into design possibilities? Check out our guide on Retaining Wall Landscaping for inspiration.

Core Benefits & Purposes

Creating level areas transforms your property’s potential completely. I’ve watched families go from having a backyard they couldn’t use to hosting graduation parties on beautiful terraced spaces.

Garden bed support goes way beyond just looking pretty. Raised beds backed by retaining walls drain better, warm up faster in spring, and make maintenance easier on your back. Plus, your plants won’t wash away during intense summer storms.

Patio support and driveway safety often get overlooked until problems develop. A well-placed retaining wall can prevent that expensive patio from settling or keep your driveway from becoming a cracked mess when the soil underneath starts moving.

For coastal clients, waterfront stabilization is serious business. Properties near water face constant erosion pressure from waves, tides, and storm surge. A properly engineered builder retaining wall can be the difference between keeping your waterfront property and watching it literally wash away.

Best Builder Retaining Wall Options for 2024

Choosing the right builder retaining wall system can feel overwhelming with all the options available today. Modern materials and techniques have made retaining walls more reliable and easier to install than ever before.

Gravity walls are the workhorses of the retaining wall world – they use their own weight to hold back soil. These walls work beautifully for shorter applications under 3-4 feet and include natural stone, concrete blocks, and timber options. The rule of thumb is simple: the base should be between half and three-quarters as thick as the wall is tall.

Cantilever walls use steel reinforcement and concrete to handle much bigger jobs than gravity walls could dream of. Instead of relying purely on weight, they use physics and leverage to resist soil pressure. These require professional design but can handle serious heights and challenging conditions.

Anchored systems use cables or rods that extend deep into the soil behind the wall. It’s like giving your wall a really strong grip on the hillside. We typically see these on very tall walls or when dealing with tricky soil conditions.

For most homeowners, the sweet spot lies with segmental retaining wall (SRW) blocks, engineered timber systems, and reinforced concrete. Each shines in different situations, and your specific site conditions, budget, and style preferences will guide the choice.

The latest research on retaining-wall types confirms what we’ve seen in the field – proper material selection based on your specific site conditions makes all the difference.

Modular Block Kits – The Fast-Track Builder Retaining Wall

Interlocking concrete blocks have completely changed the builder retaining wall game. These precision-made blocks stack together without mortar, creating surprisingly strong walls through their clever interlocking design.

Interlocking lip blocks have a built-in lip that hooks over the block below, creating a mechanical connection that prevents sliding. Most quality systems can handle walls up to 24-36 inches high without additional reinforcement – perfect for many residential applications.

Tongue-and-groove pin systems take the connection one step further. Fiberglass or plastic pins slide through holes in the blocks, locking each course to the one below. This creates an even stronger bond and allows for slightly taller walls in some cases.

What I love about these systems is how they make professional-quality results accessible to skilled DIYers. But proper base preparation and drainage are still absolutely critical. You can have the best blocks money can buy, but if you skip the foundation work, you’re setting yourself up for disappointment.

For homeowners looking for retaining wall block near me solutions, quality modular systems offer excellent value and proven durability when installed correctly.

Engineered Timber – Rustic Builder Retaining Wall With Tie-Backs

There’s something timeless about timber retaining walls that just works with New England landscapes. Modern engineered timber systems use pressure-treated lumber sized for the actual structural loads they’ll face – typically 6×6 or larger timbers.

The secret weapon in timber wall construction is the deadmen anchor system. These horizontal timbers extend back into the soil behind the wall, creating a “T” shape that essentially locks the wall into the hillside itself. For any wall over 3 feet, deadmen aren’t optional – they’re essential for long-term stability.

While modern pressure-treated lumber is safe for residential use, you’ll want to avoid old railroad ties treated with creosote. Scientific research on treated wood safety shows that modern alternatives are much preferable for home landscapes.

Timber walls do require more maintenance than concrete or stone systems – that’s the trade-off for their natural beauty. But they offer incredible flexibility for curved designs and blend seamlessly with natural settings.

Reinforced Concrete – Heavy-Duty Builder Retaining Wall for Tall Slopes

When you need to handle walls over 4 feet or deal with significant loads, reinforced concrete cantilever walls are often your best bet. These walls might look simple, but they’re engineering marvels that use steel rebar grids embedded in concrete to create incredibly strong, durable structures.

The poured footing is where the magic starts. It extends below the frost line and provides the stable foundation everything else depends on. The wall itself is relatively thin compared to a gravity wall, but it gets its strength from the steel reinforcement and the clever leverage provided by the footing design.

For really tall walls, we sometimes add counterfort ribs – think of them as concrete buttresses that tie the wall face back to the footing for extra support.

Any reinforced concrete wall over 4 feet requires design by a licensed structural engineer. The engineering fees are minimal compared to the cost of rebuilding a failed wall.

How to Choose the Right Builder Retaining Wall Contractor

Choosing the wrong contractor for your builder retaining wall project can turn your dream landscape into a nightmare. I’ve seen too many homeowners deal with failed walls, cost overruns, and legal headaches because they didn’t know what to look for.

A poorly built retaining wall doesn’t just look bad – it can fail catastrophically, potentially damaging your property or creating safety hazards. After 20 years in this business, I’ve learned that the difference between success and disaster often comes down to asking the right questions upfront.

Permits are required for walls over 4 feet in most Massachusetts communities, and some towns have even stricter requirements. A qualified contractor knows local codes inside and out and won’t leave you scrambling to fix compliance issues later.

Soil testing might seem like an unnecessary expense, but it’s crucial for proper design. Clay soils behave completely differently from sandy soils, and this affects everything from drainage design to foundation requirements.

Cost ranges for retaining walls vary dramatically – from basic installations to complex engineered systems. Costs typically range from $15 to over $100 per square foot, based on internet research, depending on materials, height, site access, and complexity. These are average costs based on internet data and not actual costs for SalCorp Landscaping. Be wary of contractors who quote significantly below market rates – they’re likely cutting corners somewhere that will cost you later.

Warranties matter. Most professional contractors offer warranties ranging from 5 to 10 years on craftsmanship and labor. This demonstrates confidence in their work and provides you with real protection.

Site access affects costs significantly. If equipment can’t reach your work area easily, labor costs increase substantially. Honest contractors assess this during the initial site visit and factor it into their proposals upfront.

Retaining Wall Design requires balancing structural requirements, aesthetic goals, and budget constraints. The best contractors help you steer these trade-offs without compromising safety or quality.

What Sets a Pro Apart

Licensed and insured should be non-negotiable. Ask to see current certificates and verify them independently. In Massachusetts, contractors working on larger projects must be licensed.

Access to engineering expertise makes a huge difference for complex projects. Some contractors maintain relationships with structural engineers, while others have engineers on staff. Either way, they should know when engineering is needed and how to get it done right.

Geogrid knowledge becomes critical for taller walls. This involves placing fabric reinforcement layers that extend back into the soil to provide additional stability. Proper installation requires specific knowledge and experience that separates pros from amateurs.

Proper equipment is essential for quality work. Plate compactors, excavation equipment, and material handling capabilities aren’t optional. Contractors who show up with hand tools for major projects are setting themselves up for failure.

Photo documentation shows professionalism and protects everyone involved. Good contractors document their work, especially critical elements like drainage installation and steel placement that will be hidden once the project is complete.

Questions to Ask Your Potential Builder Retaining Wall Partner

Ask for recent project references, preferably in your area. Good contractors are proud to show off their work and put you in touch with satisfied customers. If they hesitate or make excuses, that’s a red flag.

Material sourcing affects both quality and scheduling. Where do they get their materials? Do they have established relationships with suppliers? This can make the difference between a smooth project and constant delays.

Drainage details are absolutely critical. How specifically will they handle drainage? What type of pipe, what size gravel, how will it connect to existing drainage systems? Any contractor who glosses over drainage should be crossed off your list immediately.

Maintenance requirements vary by wall type and materials. What ongoing maintenance will be required? How should you care for the wall to maximize its lifespan? Good contractors provide clear guidance on this.

Change order policies prevent disputes later. How do they handle changes or unexpected conditions found during construction? Clear policies and fair pricing structures protect both parties.

DIY vs Professional Builder Retaining Wall – Snapshot Guide

The idea of building your own retaining wall is tempting. You scroll through YouTube videos, see the step-by-step process, and think “How hard could it be?” The potential savings make it even more appealing.

Here’s the reality: basic builder retaining wall construction follows a logical sequence, but each step has hidden complexities that can make or break your project.

The foundation work starts with marking your wall location and digging a trench 4-8 inches deep, depending on your wall height. You’ll need about 3 inches of compacted paver base before placing your first course perfectly level – and I mean perfectly. Every block that follows will reflect any mistakes you make here.

As you build up, you’ll backfill with ¾-inch gravel behind each course, installing geogrid every 2 courses for walls approaching 3 feet. The plate tamping needs to happen in 6-inch lifts, compacting each layer thoroughly before adding the next.

Sounds straightforward, right? Here’s where most DIY projects run into trouble. Proper compaction requires serious equipment and technique. I’ve seen too many “weekend warrior” walls fail because the backfill wasn’t compacted properly. The wall looks great initially, but six months later it’s leaning like the Tower of Pisa.

When we tackle a builder retaining wall project, we bring two decades of experience plus the right equipment for the job. Our Hardscaping / Retaining Walls team has seen every possible complication and knows how to handle them.

The accountability factor matters too. When you build it yourself and something goes wrong, you’re stuck with the consequences. When we build your wall, our reputation rides on its performance for years to come.

When a DIY Builder Retaining Wall Makes Sense

Walls under 3 feet using modular block systems can work well for handy homeowners who enjoy tackling projects methodically. The margin for error is more forgiving, and the structural demands are manageable.

If you have open weekends and a flexible timeline, DIY makes more sense. These projects can stretch over several weekends, letting you work at a comfortable pace without the pressure of contractor schedules.

Rental equipment is readily available in most Massachusetts communities. You can rent plate compactors, small excavators, and material handling equipment for reasonable daily rates.

Simple, straight walls without complex curves, steps, or drainage challenges are the best candidates for DIY approaches. The fewer variables involved, the better your chances of success.

When to Call a Professional Builder Retaining Wall Crew

Walls over 4 feet enter a different league entirely. The structural engineering becomes complex, permits are typically required, and the consequences of failure become much more serious.

Clay soil is particularly unforgiving. Massachusetts has plenty of clay-heavy areas, and this soil type retains water while creating enormous pressure against retaining walls. We’ve developed specific techniques for clay soil conditions that most DIYers simply don’t know about.

Surcharge loads from driveways, patios, or slopes above your wall require engineering analysis. If cars will be parking near your wall or if there’s additional weight bearing down from above, the design requirements change significantly.

Septic system proximity creates special challenges we encounter regularly in Massachusetts. Retaining walls need to be carefully positioned and designed to avoid interfering with septic systems while still providing proper drainage.

Tiered wall designs with multiple levels require precise planning. The upper walls can’t overload the lower walls, and the spacing relationships are critical for long-term stability.

Frequently Asked Questions about Retaining Wall Builders

After two decades of building retaining walls across Massachusetts, I’ve heard just about every question homeowners have about these projects. Here are the ones that come up most often – and the answers that can save you from costly mistakes.

How deep should the footing be?

The foundation is absolutely critical for any builder retaining wall project, and getting the depth right makes the difference between a wall that lasts decades and one that fails in the first few years.

For most residential block walls, we bury the first course about halfway into the ground – typically 4 to 6 inches deep. This gives the wall a solid foundation and helps it resist the forward pressure from the soil behind it.

But here’s where it gets more complex. If you’re dealing with walls over 4 feet or challenging soil conditions like clay, you’ll likely need a concrete footing that extends below the frost line. In Massachusetts, that means going down about 4 feet – yes, that’s a lot of digging, but it’s what keeps your wall from shifting during our freeze-thaw cycles.

The trench width matters too. We typically dig trenches 18 to 24 inches wide – about twice the width of the blocks we’re using. This extra space gives us room to install proper drainage and ensures we can compact the base materials correctly.

Don’t skimp on the base preparation. I’ve seen too many walls fail because someone rushed through this step, thinking they could save time or money. The foundation work might not be glamorous, but it’s what everything else depends on.

Do I really need drainage pipe on a low wall?

This is probably the most important question you can ask, and the answer is always yes – even for shorter walls. I can’t tell you how many “simple” 2-foot walls I’ve had to rebuild because someone skipped the drainage.

Here’s the thing about water pressure: it doesn’t care how tall your wall is. When soil gets saturated, it becomes incredibly heavy and pushes relentlessly against your wall. A seemingly modest wall that’s 4 feet high and 15 feet long could be holding back up to 20 tons of saturated soil. That’s the weight of about 10 cars pushing against your wall!

Proper drainage for any builder retaining wall involves several key components working together. Perforated drain pipe goes at the base of the wall, surrounded by ¾-minus gravel that allows water to flow freely to the pipe. We wrap this in filter fabric to prevent fine soil particles from clogging up the system over time.

The drain pipe needs to go somewhere useful – we slope it at least 1 inch for every 4 feet and make sure it outlets to daylight or connects to your existing drainage system. I’ve seen too many pipes that just end in the middle of a yard, creating swampy conditions and defeating the whole purpose.

Surface grading is the final piece. We shape the soil behind the wall to direct surface water away from the wall area. Think of it as creating a complete water management system, not just installing a pipe and hoping for the best.

What permits are required in Massachusetts?

Permit requirements can be tricky because they vary quite a bit from town to town, but there are some general patterns that most Massachusetts homeowners need to know about.

Most communities require permits for retaining walls over 4 feet in height. But don’t assume that shorter walls are automatically permit-free – some towns have stricter rules, especially for walls that support driveways or are close to property lines.

Structural walls that support anything – driveways, patios, or buildings – often need permits regardless of height. The building department wants to make sure these walls can handle the extra load safely.

Location matters too. Walls near property lines may have setback requirements, and if you’re dealing with septic systems, you’ll likely need health department approval. Waterfront properties face additional environmental permitting requirements that can add time and complexity to your project.

The permit process typically requires a site plan showing exactly where the wall will go, structural calculations for taller walls, a drainage plan, and construction details specifying materials and methods.

Here’s the good news: professional builder retaining wall contractors handle all this paperwork as part of their service. We know the local requirements, have relationships with building departments, and can steer the process efficiently. It’s one less headache for you and ensures everything gets done properly from the start.

Conclusion

When your yard is sliding away or you’re staring at an unusable slope, the right builder retaining wall contractor becomes your property’s best friend. After two decades of building walls that stand the test of time, I’ve learned that the difference between success and failure isn’t just about materials or techniques – it’s about finding someone who truly understands what they’re building and why it matters.

At SalCorp Landscaping & Construction, we’ve made retaining walls our specialty because we’ve seen what happens when they’re done wrong. Failed walls don’t just look bad – they can damage your property, create safety hazards, and cost far more to fix than they would have cost to build properly in the first place.

What sets us apart is simple: we’re owner-operated, which means I personally stand behind every wall we build. When you call SalCorp, you’re not getting passed around between salespeople, project managers, and subcontractors. You’re working directly with someone who has skin in the game and takes pride in craftsmanship that lasts.

Our own machinery means we can tackle projects efficiently without relying on rental equipment or subcontractors who might not share our standards. From compact excavators to plate compactors, we bring the right tools for professional results.

We’ve had the privilege of serving communities throughout Massachusetts for over 20 years – from coastal properties in Scituate dealing with erosion challenges to suburban slopes in Wellesley that needed terracing for usable space. Each project teaches us something new, and that experience shows in our work.

The truth is, a properly built builder retaining wall is an investment that pays dividends for decades. It protects your most valuable asset, creates outdoor living space you’ll actually use, and adds real value to your property. But only when it’s engineered and built correctly from day one.

Don’t let your landscape slip away while you’re shopping for the cheapest bid. The peace of mind that comes from working with experienced professionals who guarantee their work is worth every penny. More info about retaining-wall services is available on our website, where you can see examples of our work and learn more about our process.

Ready to protect your property with a builder retaining wall that’s built to last? Schedule a free site visit today. We’ll assess your specific situation, explain your options, and provide honest recommendations based on what’s best for your property – not what’s best for our bottom line.