Block Wall Builder: 7 Proven Steps for Stunning Results 2025

Why Every Property Owner Needs a Block Wall Builder

When searching for a block wall builder, you’re looking for someone who can create durable, attractive walls that serve multiple purposes – from retaining soil and preventing erosion to adding privacy and enhancing your property’s value.

What a Block Wall Builder Does:

– Retaining walls – Hold back soil on slopes and create level areas

– Freestanding walls – Provide privacy, boundaries, and decorative elements

– Garden walls – Create raised planting beds and landscape features

– Pool walls – Build safe, attractive barriers around water features

– Commercial barriers – Install security and boundary walls for businesses

Block wall construction involves much more than stacking blocks. Professional builders understand soil pressure, drainage requirements, proper foundations, and local building codes. They can build walls from 2 feet to over 40 feet high using various systems.

The choice between DIY and professional installation often comes down to wall height, soil conditions, and local regulations. Walls over 4 feet typically require engineering, while any retaining wall needs proper drainage to prevent expensive failures.

Massachusetts property owners face unique challenges with freeze-thaw cycles that can destroy poorly built walls. Premium blocks with 5000 PSI compressive strength provide superior resistance to these harsh conditions.

As Sal Musto, owner of SalCorp Landscaping & Construction, I’ve spent over two decades helping Massachusetts property owners build lasting outdoor solutions, including countless block wall builder projects that stand the test of time.

Block wall builder vocab explained:

– retaining wall design

– retaining wall landscaping

– what is a retaining wall

What You’ll Learn

In this comprehensive guide, we’ll cover everything you need to know about block wall construction. You’ll find different wall types, materials ranging from basic concrete blocks to premium interlocking systems, and the tools required for successful installation.

You’ll learn about average project costs and understand when to tackle a project yourself versus when to hire a professional block wall builder. We’ll cover maintenance requirements to help your investment last 20 to 100 years, depending on materials and construction quality.

Understanding Block Wall Systems

When hiring a block wall builder, understanding wall systems helps you make informed decisions. Block walls aren’t just stacked blocks – they’re engineered solutions handling serious forces.

Retaining walls hold back tons of soil while dealing with water pressure. Soil constantly pushes outward, especially when saturated. Walls over 2 feet high need careful planning to avoid expensive failures.

Freestanding walls create privacy and mark boundaries without fighting soil pressure, but still need solid foundations for New England’s freeze-thaw cycles.

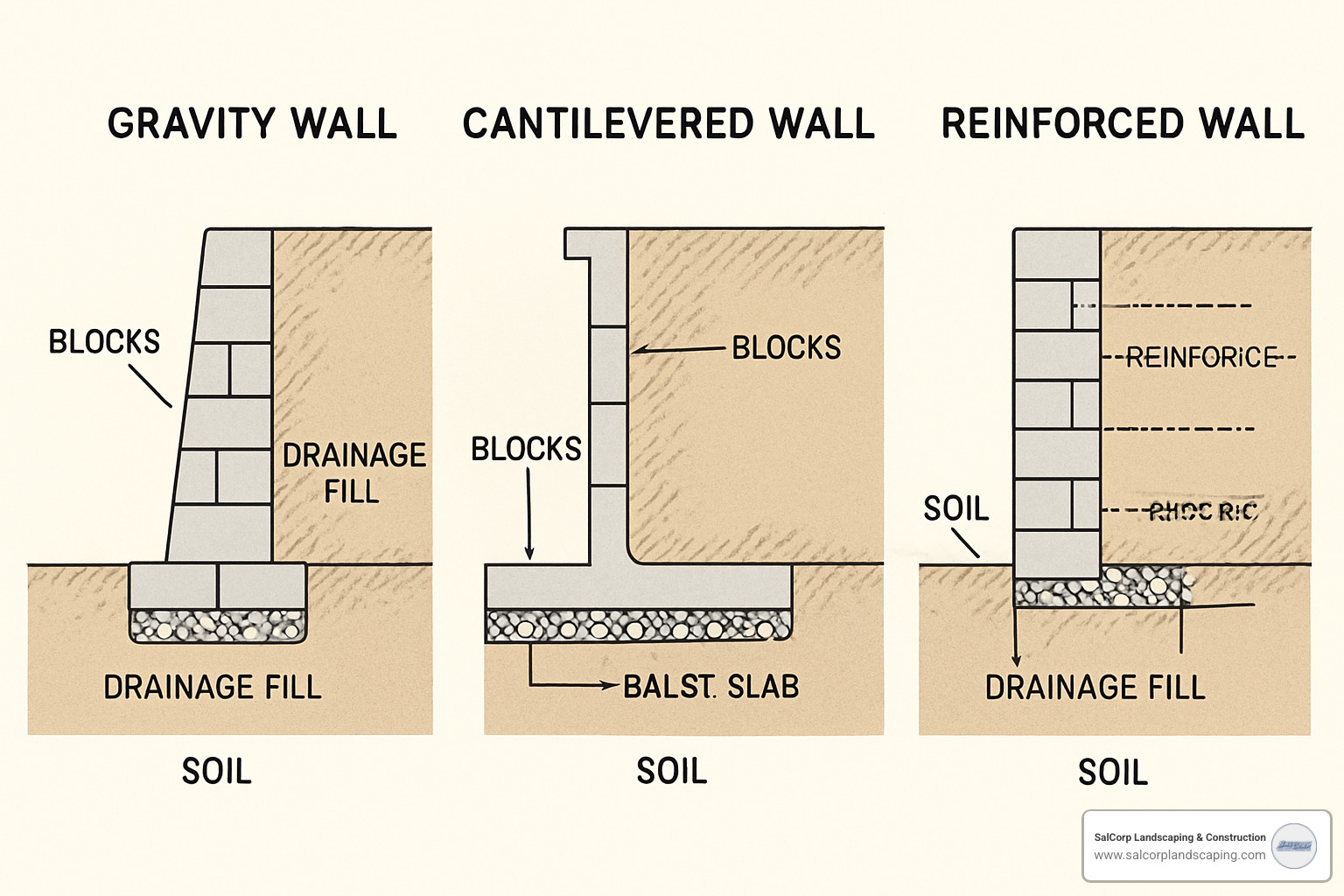

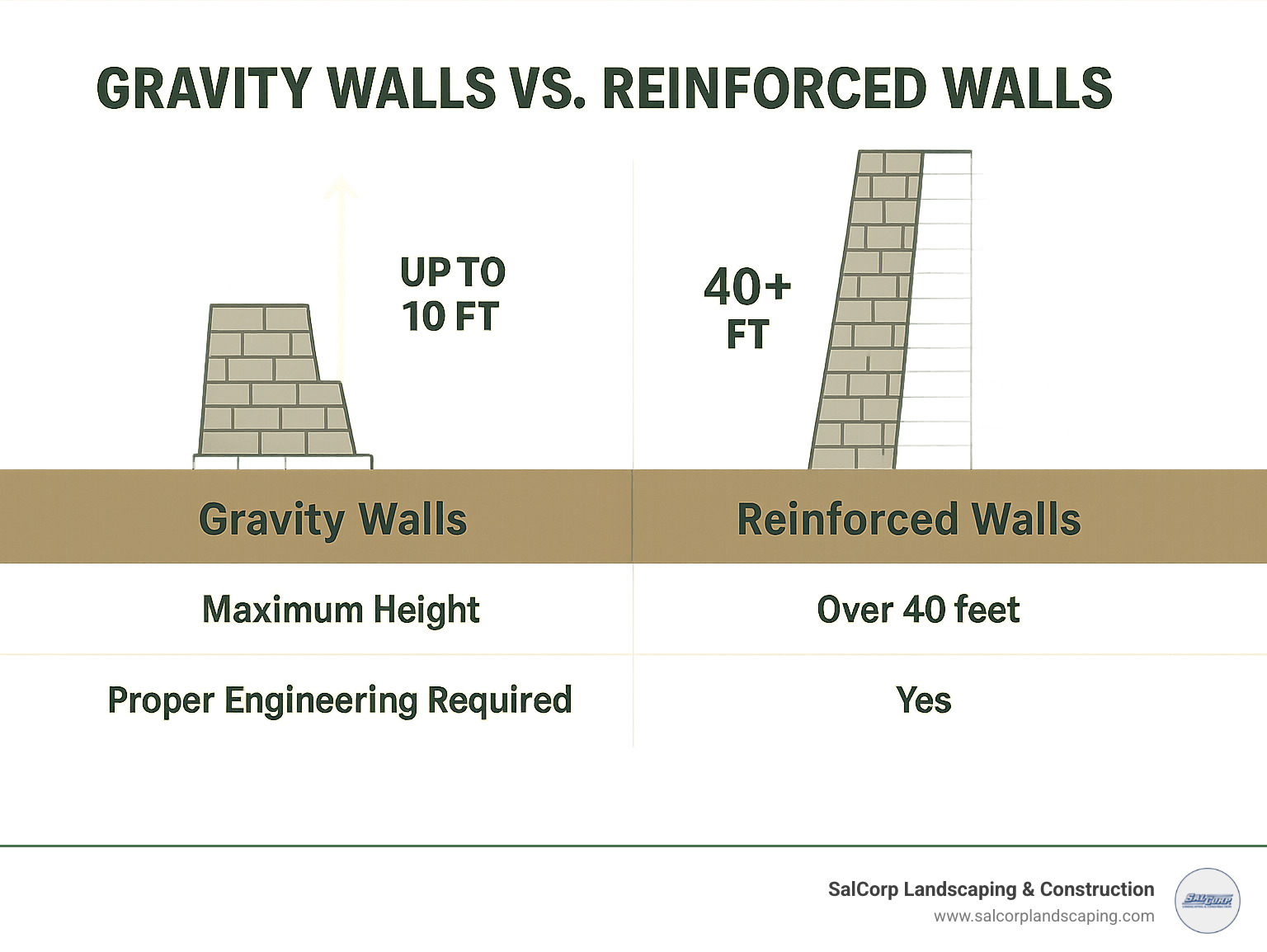

The engineering world recognizes four main retaining wall types: Gravity walls use their weight to stay put and work great up to 10 feet. Cantilevered walls use L-shaped footings that use soil weight for stability. Anchored walls use cables reaching deep into hillsides. Sheet piling walls are driven into the ground for tight spaces.

Major Wall Types & Uses

Soil retention transforms steep slopes into terraced gardens or level areas for play spaces. Seating walls at 18 inches high create built-in seating around fire pits while defining spaces. Privacy walls create outdoor rooms without fence maintenance. Erosion control protects property by managing water flow properly.

Materials & Strength Basics

Concrete blocks are the workhorses – strong, consistent, and available. In Massachusetts, I recommend blocks with 5000 PSI compressive strength minimum for freeze-thaw resistance.

Cinder blocks are lighter for DIY projects and decorative uses. Stone blocks bring natural beauty lasting centuries. Brick blocks offer classic New England looks lasting 100+ years.

Compressive strength isn’t just numbers – 5000 PSI blocks handle serious weight and resist freeze-thaw expansion that destroys cheaper blocks.

Engineering & Drainage 101

Lateral pressure from soil constantly pushes walls outward, increasing with height and water saturation. Every retaining wall needs French drain systems – perforated pipe surrounded by gravel, wrapped in landscape fabric.

Geogrid reinforcement extends into soil, making walls wider and more stable for taller construction. Soil compaction prevents settling that damages drainage systems.

Scientific research on drainage shows water management matters more than block strength for long-term performance.

Planning & Design Essentials

Proper planning prevents wall failures. Site surveys identify water flow patterns and existing utilities. Call 811 for free utility marking before digging.

Permits and building codes vary across Massachusetts. Most towns require permits for walls over 4 feet high. Wall height determines everything – gravity walls work up to 10 feet, while taller walls need reinforced systems with engineering.

Load calculations consider more than soil – driveways, trees, and runoff create additional forces requiring stronger engineering.

Choosing the Right Block System

Interlocking SRW systems revolutionized construction with mortarless installation using lips, pins, and mechanical connections. Modular panel systems install faster with cleaner lines. Veneer options combine structural concrete with decorative faces.

More info about hardscape walls covers New England-specific design considerations.

Layout, Footings & Base Prep

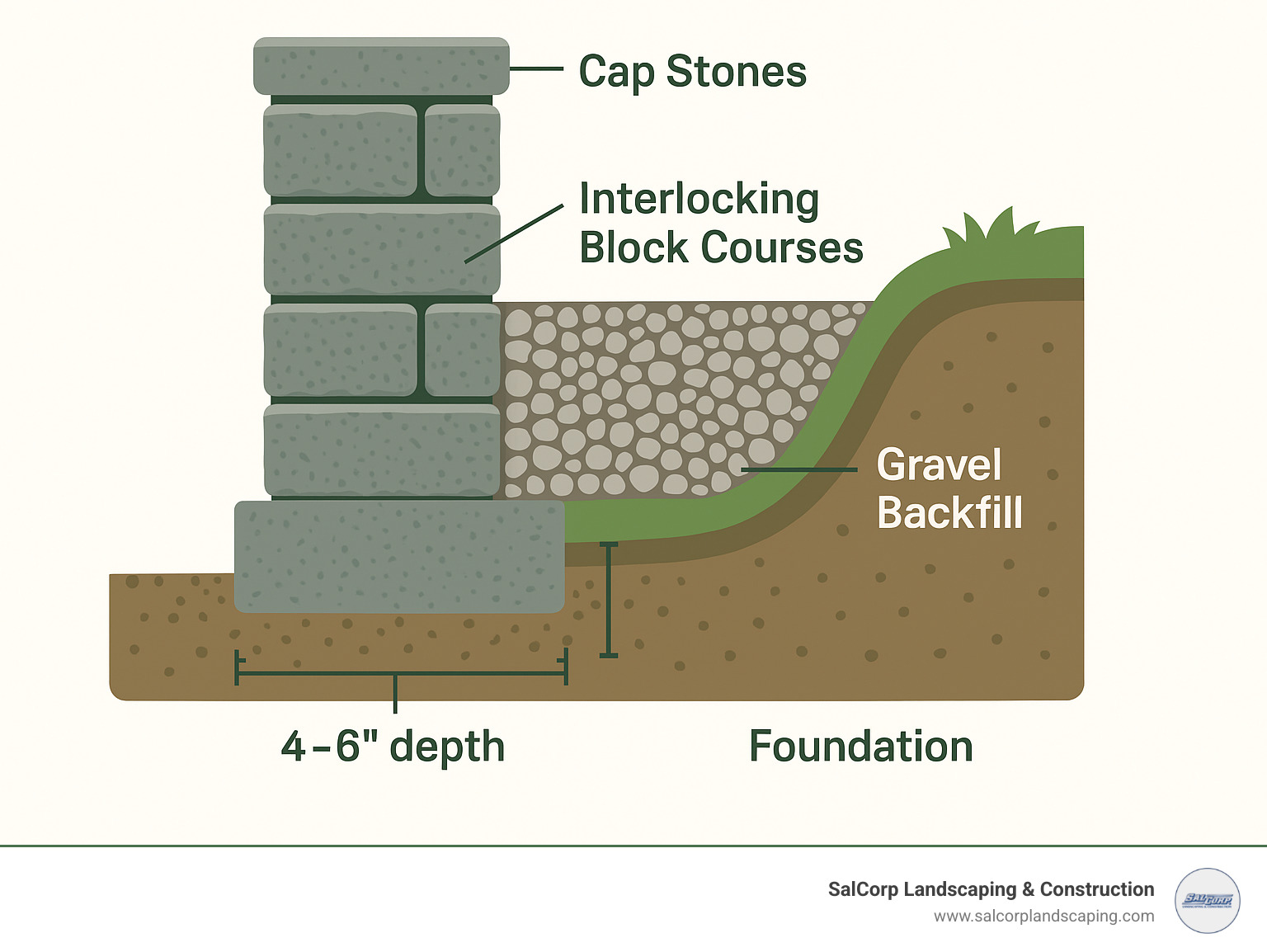

Trench depth should be 4-6 inches, burying half the first course. Base width should be twice block width – roughly 12 inches for standard blocks. Use 3-4 inches of compacted gravel in thin layers.

Getting your first course perfectly level is critical since errors compound with each course.

Tools & Equipment Checklist

Basic tools include 4-foot level, rubber mallet, measuring tape, and marking tools. Masonry saws with diamond blades cut blocks cleanly. Compaction equipment prevents settling. BOBB lift systems handle 150-pound blocks safely for larger projects.

Step-by-Step Guide: The Block Wall Builder Method

Building successful block walls requires following a proven system. Step planning must account for drainage, base preparation, and finishing details before moving dirt.

Block stacking requires technique – each course overlaps joints below by 6 inches minimum. Construction adhesive between courses seals out water and creates unified structure. Cap stones protect everything below while providing finished appearance. Backfill operations can make or break walls if done incorrectly.

Block Wall Builder’s Seven Steps

Excavation starts with 811 utility marking. Trench should be 4-6 inches deep, 12 inches wide, with level bottom.

Leveling pad preparation uses 3-4 inches of compacted base material, truly compacted and level.

First course installation gets buried halfway for stability and frost protection. Every block must be perfectly level and aligned.

Drainage pipe installation happens after first course – perforated pipe behind wall, surrounded by gravel, wrapped in fabric.

Successive courses build height while maintaining integrity. Apply adhesive between courses, stagger joints, check plumb constantly.

Backfill layers get placed and compacted as you build – clean material in 6-inch lifts.

Finishing caps complete projects with protection and style, secured with adhesive.

Quality Control & Longevity

Plumb checks should happen every course using 4-foot level. Staggered joints provide structural integrity with 6-inch minimum overlap. Pin systems in modern blocks provide mechanical connection handling freeze-thaw cycles.

Premium blocks with 5000 PSI strength resist Massachusetts weather better than standard blocks. Penetrating sealants extend life while allowing walls to breathe. Proper techniques extend wall life from 20 years to 100+ years.

Choosing Your Block Wall Builder & Budget

When selecting a block wall builder, credentials matter more than low bids. Look for proper licensing, insurance, and references from recent similar projects.

Licenses vary by state – verify current status through licensing boards. Insurance should include liability and workers’ compensation. References from recent clients provide insight into quality and service.

Signs You Need a Professional Block Wall Builder

Cracking in existing walls indicates structural problems requiring professional assessment. Leaning walls are safety hazards needing immediate attention. Heights over 4 feet typically require engineering and professional installation.

Complex loads from driveways or steep slopes require specialized knowledge. Poor soil conditions including clay or high water tables need professional expertise.

More info about masonry contractors provides additional contractor selection guidance.

DIY vs Hiring a Block Wall Builder

Skill requirements vary significantly with wall type and height. Simple garden walls may suit DIY, while retaining walls typically need professionals. Labor hours average 40-50 hours for typical DIY installations. Equipment access can be expensive for specialized tools.

Average Project Costs & Factors

Based on internet research data (not actual SalCorp Landscaping costs), average costs range from $20-$65 per square foot, with high-end projects reaching $200+ per square foot for complex designs.

Excavation costs depend on soil conditions and access. Drainage upgrades may add substantial costs. Finishes including caps and lighting can double basic costs.

Design Upgrades & Curb Appeal

Textured faces provide visual interest complementing architecture. Mixed colors create custom appearances. Lighting integration transforms walls into nighttime focal points. Seating caps combine function with protection.

Maintenance, Repairs & Innovations

Regular inspection should happen annually, checking for cracks, settlement, or leaning. Cleaning removes damaging organic growth. Re-pointing mortared joints maintains weather resistance every 10-15 years.

Sealant re-application protects from freeze-thaw damage every 3-5 years using penetrating sealers. Address crack repair promptly to prevent water infiltration.

With proper maintenance, lifespan expectations range from 20 years for basic installations to 100+ years for premium materials.

Latest Trends & Tech

Large-format blocks speed installation – some weigh over 12,000 pounds, achieving 1,500 square feet per day installation rates. Lightweight pins replace mortar systems, providing structural integrity while allowing movement.

Eco-blocks from recycled materials appeal to environmentally conscious owners. Modular fascia systems allow mixing decorative faces with structural backing.

When & How to Repair

Crumbling mortar is usually maintenance rather than structural issues – good DIY project for handy homeowners. Bulging walls indicate serious problems requiring immediate professional attention.

Water stains suggest drainage problems to address before structural damage. Partial rebuilds may be necessary for failed sections. Tie-back retrofits can sometimes stabilize failing walls without complete reconstruction.

More info about retaining wall blocks covers repair options for different block types in New England conditions.

Frequently Asked Questions about Block Wall Building

What are the main wall styles I can build?

Gravity retaining walls use their weight to hold back soil, working beautifully up to 10 feet high. Reinforced walls incorporate geogrid for taller applications or challenging conditions. Freestanding walls create privacy and boundaries without retaining soil. Seating walls at 18-24 inches high combine beauty with function around patios and fire pits.

How deep should my footing be?

Bury the first course 4-6 inches deep in a 12-inch-wide trench – basically twice your block width. This provides stability and frost protection essential for New England conditions. Taller walls or challenging soil may require deeper foundations with professional engineering.

Can I build a block wall without mortar?

Absolutely! Mortarless construction has become preferred for modern walls. Interlocking block systems use mechanical connections rather than mortar, installing faster and handling freeze-thaw cycles better. Pin systems provide structural integrity while allowing natural thermal movement. This approach has ancient roots but modern engineering has refined it with better materials and manufacturing.

Conclusion

Building successful block walls creates lasting value for your property. Durable walls result from understanding that proper planning, quality materials, and solid construction techniques make the difference between walls lasting 20 years versus a lifetime.

Quality materials with 5000 PSI compressive strength paired with proper drainage systems create walls that withstand Massachusetts winters. The choice between DIY and hiring a professional block wall builder depends on project complexity and your comfort level.

For Massachusetts property owners wanting professional results, SalCorp Landscaping & Construction has created beautiful, lasting hardscape solutions for over two decades. Our owner-operated approach ensures attention to detail that transforms properties and how families enjoy outdoor spaces.

Ready to explore your property’s potential? More info about Hardscape Construction provides additional resources for planning your next outdoor construction project.