Retaining Wall Installation: 10 Powerful Benefits in 2025

Why Professional Retaining Wall Installation Matters More Than You Think

Retaining wall installation is a complex engineering project that requires precise planning, proper drainage systems, and structural expertise to prevent costly failures. Here’s what you need to know when searching for professional installation services:

Key Requirements for Successful Installation:

- Proper drainage – Hydrostatic pressure is the #1 cause of wall failure

- Engineered footings – Walls over 4 feet typically require professional engineering

- Quality materials – Concrete blocks, natural stone, or timber systems each have specific applications

- Permit compliance – Most municipalities require permits for walls over 3-4 feet

- Site preparation – Stable subsoil, proper excavation, and utility location are critical

The research shows that 75% of homeowners reported increased enjoyment of their property after completing landscape projects that included retaining walls. But retaining walls aren’t just stacked blocks holding back dirt.

They’re engineered structures that must resist lateral earth pressure, manage groundwater, and withstand freeze-thaw cycles. When water saturates the soil behind your wall, the pressure can increase dramatically – turning a simple landscaping project into a structural nightmare if not done correctly.

Professional installation ensures proper drainage systems, appropriate materials for your specific soil conditions, and compliance with local building codes. DIY attempts often fail because homeowners underestimate the importance of base preparation, drainage management, and understanding when geogrid reinforcement is needed.

I’m Sal Musto, and over two decades of retaining wall installation projects in Massachusetts have taught me that the difference between a wall that lasts 30 years versus one that fails in 3 years comes down to understanding the science behind soil pressure and water management. At SalCorp Landscaping & Construction, we’ve seen too many expensive DIY failures to recommend anything other than professional installation for walls over 2 feet high.

Key terms for retaining wall installation:

Why Going Pro Matters

When we evaluate failed DIY retaining walls, three critical factors consistently emerge: safety, machinery requirements, and drainage science. Professional installation isn’t just about having the right tools – it’s about understanding the complex interplay between soil mechanics, water management, and structural engineering.

Safety considerations go far beyond wearing safety glasses. Retaining walls over 4 feet high can exert thousands of pounds of lateral pressure. If that wall fails, it can cause serious injury or property damage. Professional installers understand load calculations, proper setback angles, and when structural reinforcement is absolutely necessary.

Machinery requirements are often underestimated by DIY enthusiasts. Proper excavation requires reaching stable subsoil, which can be 2-3 feet below grade. We use mini-excavators, laser levels, and specialized compaction equipment to ensure every layer meets engineering specifications.

Drainage science is where most DIY projects fail catastrophically. Installing a perforated pipe isn’t enough – you need to understand hydrostatic pressure, frost depth considerations, and how different soil types affect water movement. Clay soils with poor drainage can create pressure that destroys improperly designed walls within a few freeze-thaw cycles.

Professional installation also comes with long-term warranty protection. When we install a retaining wall, we’re confident enough in our work to guarantee it. DIY failures often require complete reconstruction, making the “savings” from doing it yourself disappear quickly.

Product Roundup: Best Wall Types & Materials for Every Yard

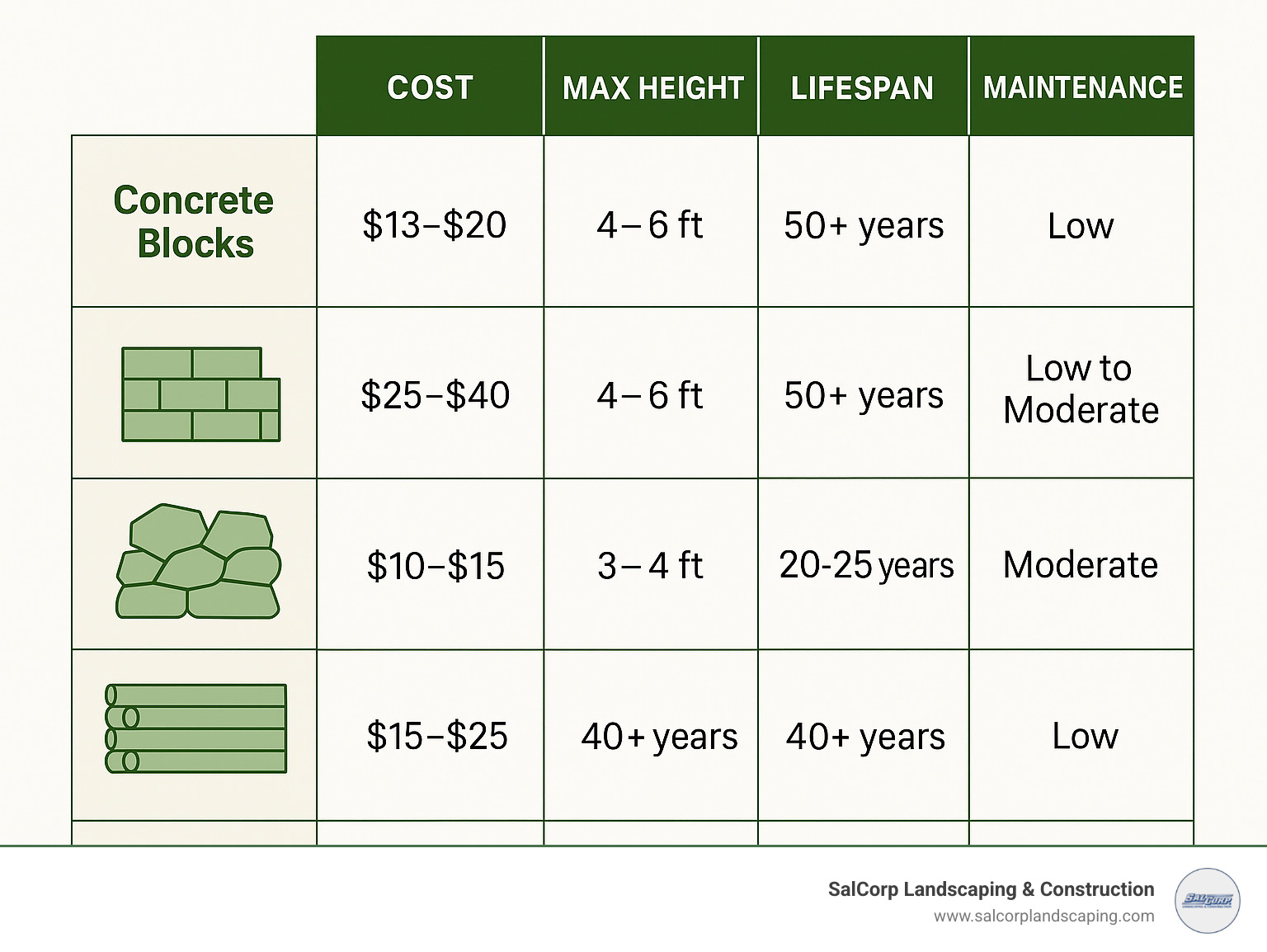

Understanding the different types of retaining walls and their applications is crucial for making informed decisions about your landscape project. Each system has specific strengths, limitations, and ideal use cases based on your site conditions and requirements.

Gravity walls rely on their own weight to resist soil pressure. These work well for walls under 4 feet high and are typically constructed from concrete blocks, natural stone, or timber. The key advantage is simplicity – no reinforcement required for shorter walls in stable soil conditions.

Cantilever walls use reinforced concrete with a footing that extends under the retained soil. This design leverages the weight of the soil itself to provide stability, making it ideal for walls 4-10 feet high. These require professional engineering but can handle significant loads.

Piling walls use vertical supports driven deep into stable soil or bedrock. These are typically reserved for extreme conditions like very tall walls or poor soil conditions. Installation requires specialized equipment and engineering expertise.

Anchored walls incorporate tie-backs or soil anchors extending into the retained soil mass. These systems can handle extreme heights and loads but require significant engineering and specialized installation techniques.

For material selection, we evaluate several factors: required height, soil conditions, aesthetic preferences, budget, and long-term maintenance requirements. Here’s how the most popular options compare:

Our Retaining Wall Design service helps match the right system to your specific site conditions and aesthetic goals.

Concrete & Modular Block All-Stars

Concrete and modular block systems dominate the residential retaining wall installation market for good reason – they combine structural reliability with relatively straightforward installation.

Interlocking lip systems feature built-in flanges that create mechanical connections between courses. This design provides excellent stability and allows walls to be built 24-36 inches high without additional reinforcement.

Pin-system blocks use fiberglass or plastic pins inserted through pre-formed holes to connect courses. This creates a more secure mechanical connection than gravity alone, allowing for taller walls and better resistance to lateral movement.

Rear-lip locator systems speed installation by providing consistent setback automatically. This feature reduces installation time and improves consistency across long wall runs.

While these systems are often marketed as “DIY-friendly,” we’ve seen enough failures to recommend professional installation for any wall over 2 feet high. The difference between success and failure often comes down to base preparation, drainage installation, and understanding when geogrid reinforcement is needed.

Concrete blocks excel in freeze-thaw conditions common in Massachusetts. The dense, low-porosity concrete resists water penetration that can cause cracking during winter months.

Natural Stone & Boulder Classics

Natural stone retaining walls offer best aesthetic appeal and can last centuries when properly constructed. We’ve restored stone walls in Massachusetts that were built in the 1800s and are still structurally sound today.

The rustic look of natural stone complements traditional New England architecture perfectly. Fieldstone, granite, and limestone each offer different visual characteristics and structural properties.

High mass is both an advantage and a challenge with natural stone. The weight provides excellent stability for gravity walls, but transportation and installation require specialized equipment. We use mini-excavators with hydraulic thumbs to position large stones safely and precisely.

Frost resistance varies significantly among stone types. Granite and other igneous rocks handle freeze-thaw cycles exceptionally well, while some sedimentary stones can deteriorate over time.

Natural stone installation requires significant expertise. Unlike modular blocks with standardized dimensions, each stone is unique. Proper fitting requires experience reading stone grain, understanding how different shapes interlock, and knowing which stones can bear the most load.

Timber & Composite Alternatives

Timber retaining walls offer the most budget-friendly option for many homeowners, but they come with significant limitations that must be understood before installation. When properly designed and installed, timber walls can provide 15-20 years of service life.

Budget considerations make timber attractive, but the total cost of ownership includes replacement cycles. A concrete block wall might cost 50% more initially but last three times longer, making it more economical over time.

Treated lumber must be rated for ground contact and structural use. We use only lumber treated with ACQ or similar preservatives that resist rot and insect damage. Proper drainage behind timber walls is even more critical than other systems because wood deteriorates rapidly when constantly wet.

The research indicates that wooden retaining walls are not recommended above 10 feet due to structural limitations and increased fire risk. For Massachusetts applications, we typically limit timber walls to 4 feet maximum height.

Specialty Systems & Reinforcements

Advanced retaining wall systems address specific challenges that standard gravity walls cannot handle. These engineered solutions allow for taller walls, poor soil conditions, and extreme loading situations.

Gabion cages filled with stone offer excellent drainage and flexibility. These wire mesh containers can accommodate ground movement without structural failure, making them ideal for areas with unstable soils.

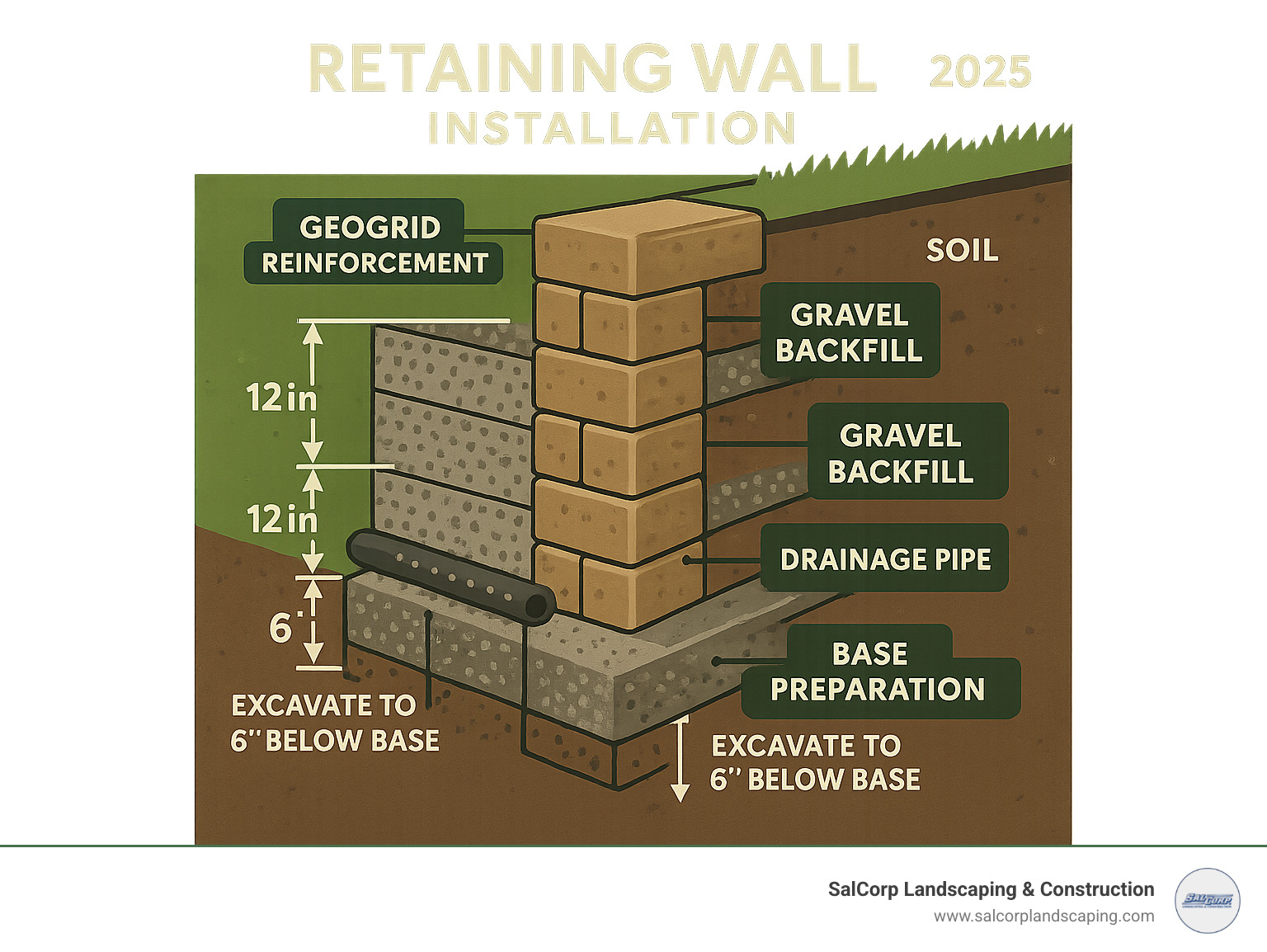

Geogrid layers transform standard block walls into reinforced earth structures. These high-strength polymer grids extend into the backfill soil, creating a composite structure that can handle significant loads. The research shows that geogrid is typically required for walls over 3 feet high or when supporting heavy loads like driveways.

Tie-backs and soil anchors extend the effective footprint of the wall deep into the retained soil mass. These systems can handle extreme heights and loads but require specialized equipment and engineering expertise.

Drainage mat systems provide superior water management compared to traditional gravel backfill. These synthetic materials maintain drainage capacity even under load and resist clogging from soil fines.

Professional engineering is typically required for these specialty systems. The complexity of design calculations, material specifications, and installation requirements make these inappropriate for DIY installation.

Planning, Permits & Pricing Guide

Successful retaining wall installation begins long before the first shovel hits the ground. Proper planning addresses site conditions, regulatory requirements, and realistic cost expectations to ensure your project succeeds both structurally and financially.

Site survey requirements go beyond measuring wall length and height. We evaluate soil conditions, existing drainage patterns, utility locations, and access for equipment. Soil testing reveals bearing capacity, drainage characteristics, and potential issues like expansive clay or organic soils that require special handling.

Soil testing is particularly important in Massachusetts where glacial deposits created highly variable soil conditions. Clay soils require different design approaches than sandy soils, and organic soils may require removal and replacement.

Frost depth considerations are critical in our climate. Footings must extend below the frost line to prevent heaving, which varies from 30 inches in coastal areas to 48 inches in western Massachusetts.

Utilities location through Dig Safe (811) is mandatory before excavation. We’ve encountered everything from gas lines to fiber optic cables in retaining wall locations.

Zoning codes and homeowner association requirements can affect wall placement, height, and materials. Some communities have specific aesthetic requirements or setback restrictions that must be addressed during planning.

Hydrostatic pressure calculations determine drainage requirements and structural design. The research consistently identifies inadequate drainage as the primary cause of retaining wall failure.

Accessibility for equipment affects both installation methods and costs. Walls that require hand-digging and manual material placement cost significantly more than those accessible to excavation equipment.

The labor range for professional installation reflects the complexity and skill required. According to our research, labor costs typically range from $50-100 per linear foot, but this can vary significantly based on site conditions, wall height, and access requirements.

Material costs vary widely based on system selection, local availability, and project scale. The research indicates costs from $50-150 per linear foot for every 6 inches of height, but premium materials and complex sites can exceed these ranges.

Value return studies show that landscape redesigns including retaining walls achieve 105% value recovery according to National Association of Realtors research. This makes professional installation a sound investment in both functionality and property value.

For detailed cost analysis, visit our How Much Does a Retaining Wall Cost? resource page.

Average Cost of Retaining Wall Installation in Massachusetts

Understanding realistic cost expectations helps homeowners make informed decisions about retaining wall installation projects. These figures represent average costs based on internet research and are not actual pricing for SalCorp Landscaping services.

Square footage pricing typically ranges from $20-60 per square foot for standard installations. However, complex sites, premium materials, or specialty systems can push costs to $100-180 per square foot. The wide range reflects the significant variables in retaining wall projects.

Linear foot pricing of $50-150 per linear foot assumes standard 4-foot wall heights. Taller walls require exponentially more materials and engineering, while shorter walls may have higher per-foot costs due to fixed setup expenses.

Footings and foundation work often add 20-30% to base costs. Concrete footings for cantilever walls, deep excavation for poor soils, or specialized base preparation for challenging conditions all increase project costs.

Engineering fees for walls over 4 feet typically range from $1,500-5,000 depending on complexity. While this seems expensive, proper engineering prevents costly failures and ensures code compliance.

Important disclaimer: These are average costs based on internet research and industry data. Actual costs vary significantly based on site conditions, material selection, access requirements, and local market conditions. SalCorp Landscaping provides detailed estimates based on specific project requirements.

Additional cost factors include:

- Permit fees ($100-500 typical)

- Soil testing ($300-800)

- Utility location and protection

- Site preparation and cleanup

- Drainage system installation

- Landscape restoration

Permits, Engineering & Code Red Tape

Navigating the regulatory requirements for retaining wall installation can be complex, but understanding the rules prevents costly delays and ensures structural safety. Massachusetts municipalities generally follow consistent guidelines, but local variations exist.

The 4-foot rule appears consistently across our research – walls over 4 feet high typically require professional engineering and building permits. Some communities lower this threshold to 3 feet, while others have specific requirements for walls near property lines or supporting structures.

Stamped engineering plans must be prepared by a Massachusetts Registered Professional Engineer for tall walls or complex conditions. These plans include structural calculations, material specifications, and construction details that ensure safety and code compliance.

Inspection milestones typically occur at excavation completion, footing installation, and final construction. Some communities require geogrid placement inspections for reinforced walls.

Building departments also consider:

- Setback requirements from property lines

- Height restrictions in residential zones

- Drainage impact on neighboring properties

- Accessibility compliance for commercial projects

- Environmental regulations near wetlands or water bodies

Working with experienced contractors familiar with local requirements streamlines the permit process and ensures compliance with all applicable codes.

The Professional Retaining Wall Installation & Maintenance Roadmap

Professional retaining wall installation follows a systematic process that ensures structural integrity, proper drainage, and long-term performance. Each step builds on the previous work, and shortcuts at any stage can compromise the entire project.

Survey and stakeout establishes precise wall alignment, elevation, and critical dimensions. We use laser levels and GPS equipment to ensure accuracy, particularly important for long walls or complex geometries.

Trench excavation must reach stable subsoil capable of supporting the wall loads. The research consistently shows that excavation depth should be 8 inches deeper than one block height, with width twice the block depth.

Gravel base installation provides a stable, level foundation for the wall. We use 6 inches of 3/4-inch crushed stone (ASTM No. 57) compacted in two lifts. The research emphasizes that pea gravel should never be used – angular crushed stone provides superior compaction and stability.

First course placement is critical because any errors multiply through subsequent courses. We use string lines and laser levels to ensure perfect alignment and elevation. The first course should be buried approximately 1 inch for every 8 inches of wall height according to our research.

Drainage pipe installation behind the base course prevents hydrostatic pressure buildup. We use 4-inch perforated pipe with protective sleeves, ensuring proper slope to daylight drainage. The research shows this is essential for all walls over 4 feet high and recommended for shorter walls in poor-draining soils.

Backfill and compaction occur in lifts no higher than 18 inches. We use clean, angular gravel for the first 14 inches behind the wall face, then transition to suitable soil materials. Each lift is compacted to 95% standard proctor density.

Geogrid placement follows engineering specifications for reinforced walls. The research indicates that biaxial geogrid provides superior performance compared to uniaxial alternatives.

Capstone installation provides weather protection and finished appearance. We use construction adhesive to secure caps and ensure proper overhang for water shedding.

Final grading directs surface water away from the wall on both sides. We maintain 2-5% slopes as recommended in the research and establish positive drainage to prevent ponding.

Seasonal inspection identifies potential issues before they become major problems. We recommend annual inspections focusing on drainage function, joint integrity, and signs of movement.

Minor repairs addressed promptly prevent major failures. Common maintenance includes cleaning weep holes, repairing damaged caps, and addressing vegetation growth that can damage wall structure.

For specialized applications, visit our Garden Retaining Wall and Cape Cod Retaining Walls pages.

Additional information about retaining wall engineering principles is available through this retaining wall reference.

Step-by-Step Professional Retaining Wall Installation

The precision required for successful retaining wall installation becomes apparent when examining each construction step in detail. Professional installation follows proven sequences that ensure quality and prevent costly errors.

Layout and string lines establish reference points for the entire project. We set up batter boards beyond the excavation area and use high-visibility string lines to maintain alignment. Laser levels provide elevation control, particularly important for long walls or complex profiles.

Subsoil compaction creates a stable foundation that won’t settle over time. We use vibratory plate compactors or pneumatic tampers to achieve required density. The research emphasizes that stable subsoil is essential – we excavate until reaching suitable bearing material.

Base leveling requires precision that affects every subsequent course. We screed the gravel base using 1/8-inch chip stone over pipes, then remove the pipes and fill voids. This creates a perfectly level surface for the first course.

Joint staggering provides structural integrity by preventing continuous vertical joints. We start alternate courses with half-blocks, maintaining running bond patterns. Proper joint staggering distributes loads and prevents wall failure.

Adhesive application for cap blocks requires weather-appropriate products and proper surface preparation. We clean block surfaces, apply adhesive in consistent beads, and ensure proper cap alignment before the adhesive sets.

Quality control throughout installation includes:

- Checking level and alignment after each course

- Verifying backfill compaction with density testing

- Inspecting drainage system function

- Documenting construction progress with photos

- Maintaining clean work areas for safety

Post-Build Care & Red-Flag Checklist

Even properly installed retaining walls require ongoing attention to maintain peak performance. Understanding what to watch for helps identify issues before they become expensive problems.

Weep hole maintenance is critical for drainage function. We recommend annual cleaning of weep holes and drainage outlets to prevent clogging. Blocked drainage quickly leads to hydrostatic pressure buildup and potential wall failure.

Frost heave indicators include seasonal movement, gaps between blocks, or tilting. Massachusetts freeze-thaw cycles can affect walls with inadequate footings or poor drainage.

Leaning or bulging blocks indicate structural problems requiring immediate attention. These symptoms often result from inadequate base preparation, poor drainage, or loads exceeding design capacity.

Vegetation control prevents root damage and maintains drainage function. We recommend removing vegetation growing in wall joints and maintaining clear zones around drainage outlets.

Warning signs requiring professional evaluation:

- Visible movement or tilting

- Cracks in concrete blocks or mortar joints

- Water staining or efflorescence

- Gaps between wall sections

- Drainage system failures

- Soil erosion around the wall base

Regular maintenance preserves your investment and prevents minor issues from becoming major repairs. Our Cape Cod Retaining Walls page includes specific maintenance recommendations for coastal conditions.

Frequently Asked Questions about Retaining Wall Installation

How tall can I build without engineering approval?

The height limit for retaining walls without professional engineering varies by municipality, but 4 feet is the most common threshold in Massachusetts. Some communities reduce this to 3 feet, while others consider additional factors like proximity to property lines or supported loads.

The research consistently shows that walls over 36 inches typically require permits, and walls over 4 feet need engineered drawings. This isn’t arbitrary – taller walls experience exponentially higher soil pressures that require structural analysis to handle safely.

Even walls under the engineering threshold benefit from professional design. Soil conditions, drainage requirements, and local climate factors all affect wall performance. We’ve seen 3-foot walls fail catastrophically due to poor drainage, while properly designed 6-foot walls perform flawlessly for decades.

Do I always need a drain pipe behind the wall?

Drainage requirements depend on wall height, soil conditions, and local climate. The research indicates that all walls over 4 feet high should include drainage pipes, and shorter walls benefit from drainage in poor-draining soils.

Massachusetts clay soils hold water and create hydrostatic pressure that can destroy walls. Sandy soils drain naturally but may still require drainage pipes for taller walls or areas with high groundwater.

We recommend drainage pipes for virtually all retaining walls because the cost of installation is minimal compared to the cost of wall failure. Proper drainage extends wall life and prevents the majority of structural problems.

When should I choose geogrid reinforcement?

Geogrid reinforcement transforms a gravity wall into a reinforced earth structure capable of handling much higher loads. The research shows geogrid is typically required for walls over 3 feet high or when supporting heavy loads like driveways.

Soil conditions also influence geogrid requirements. Poor soils with low bearing capacity benefit from geogrid reinforcement even for shorter walls. Engineering analysis determines specific geogrid requirements based on soil properties and loading conditions.

The cost of geogrid is relatively modest compared to the increased capacity it provides. When properly installed, geogrid allows standard block walls to reach heights of 10-15 feet while maintaining structural integrity.

Conclusion

Professional retaining wall installation represents a significant investment in your property’s functionality, safety, and value. The research clearly demonstrates that landscape projects including retaining walls achieve 105% value recovery, making them one of the most financially sound home improvements available.

The project value extends beyond financial returns to include increased usable space, improved drainage, and improved outdoor living opportunities. Properly designed retaining walls can transform unusable sloped areas into functional landscape features that serve your family for decades.

Curb appeal improvements from professional retaining walls are immediate and long-lasting. Quality materials and expert installation create landscape features that complement your home’s architecture while providing practical benefits like erosion control and space creation.

Structural security comes from understanding the engineering principles behind soil pressure, drainage management, and material selection. The research consistently shows that inadequate drainage and poor base preparation cause the majority of retaining wall failures – problems that professional installation prevents.

Single contact point service simplifies your project from design through completion. At SalCorp Landscaping & Construction, our 20+ years of experience in Massachusetts means we understand local soil conditions, climate challenges, and regulatory requirements that affect retaining wall performance.

Our owner-operated approach ensures accountability and quality control throughout your project. We use our own equipment and trained crews to maintain consistent standards, and we stand behind our work with comprehensive warranties.

Whether you’re dealing with erosion problems, need to create usable space, or want to improve your landscape’s functionality, professional retaining wall installation provides solutions that DIY approaches simply cannot match. The complexity of proper drainage design, structural engineering, and long-term performance requirements make professional installation essential for lasting results.

From our base in Walpole, we serve communities throughout Massachusetts including Boston, Newton, Wellesley, Needham, and the Cape Cod region. Our local knowledge and specialized equipment ensure your retaining wall project meets the highest standards for structural integrity and aesthetic appeal.

For comprehensive information about our retaining wall services, visit our retaining wall contractor services page or contact us for a detailed consultation about your specific project requirements.